In recent years, the manufacturing industry has witnessed a significant transformation, primarily driven by advancements in technology. One of the most notable innovations is the large 3D printer with superior printing capacity. These machines are not just enhancing production capabilities; they are redefining what is possible in manufacturing.

Understanding Large 3D Printers

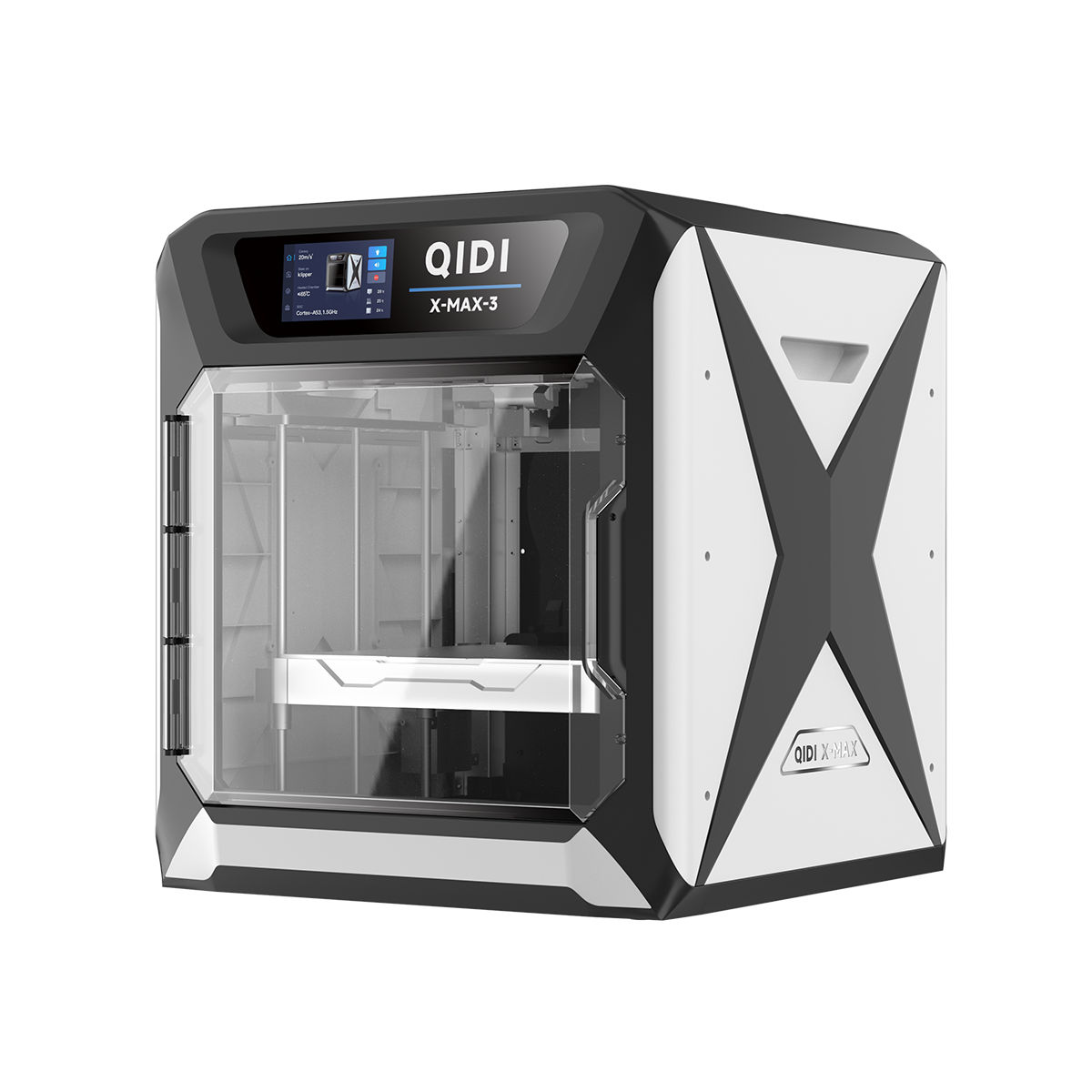

A large 3D printer with superior printing capacity is designed to produce larger objects with intricate details and high precision. Unlike traditional 3D printers, which are often limited in size and material options, these advanced machines can handle a variety of materials, including metals, plastics, and composites. This versatility opens up new avenues for industries ranging from aerospace to healthcare.

Key Features of Large 3D Printers

- Enhanced Build Volume: The ability to print larger objects reduces the need for assembly, saving time and resources.

- Material Versatility: These printers can work with multiple materials, allowing for complex designs and applications.

- High Precision: Superior printing capacity ensures that even the most intricate designs are produced with exceptional accuracy.

- Cost Efficiency: By minimizing waste and reducing production time, large 3D printers can significantly lower manufacturing costs.

Applications Across Industries

The applications of a large 3D printer with superior printing capacity are vast and varied. For instance, in the aerospace industry, these printers are used to create lightweight components that enhance fuel efficiency. In healthcare, they are revolutionizing the production of prosthetics and implants tailored to individual patients. How might these advancements impact your industry? The possibilities are endless.

Benefits of Adopting Large 3D Printing Technology

Adopting this technology can lead to numerous benefits:

- Faster Prototyping: Rapid prototyping allows companies to test designs quickly and efficiently.

- Customization: Products can be tailored to meet specific customer needs, enhancing satisfaction.

- Reduced Lead Times: Shorter production cycles mean that companies can respond more swiftly to market demands.

Investing in the Future

As industries continue to evolve, investing in a large 3D printer with superior printing capacity is becoming increasingly essential. Companies like  are leading the charge in providing high-quality, reliable 3D printing solutions. By embracing this technology, businesses can stay ahead of the competition and meet the growing demands of their customers.

are leading the charge in providing high-quality, reliable 3D printing solutions. By embracing this technology, businesses can stay ahead of the competition and meet the growing demands of their customers.

Conclusion

In conclusion, the emergence of large 3D printers with superior printing capacity is revolutionizing the manufacturing landscape. With their ability to produce larger, more complex parts with high precision, these machines are paving the way for a more efficient and innovative future. As we look ahead, it is clear that embracing this technology will be crucial for companies aiming to thrive in an increasingly competitive market.